BPD Bearing Protection Device for Pumps

2 Common Pump Problems; 1 Solution…….. the BPD

Problem 1: Pumps routinely operate in high humidity and dirty environments. They are also commonly operating batch processes meaning the pump is cycled on and off. These operating conditions results in contamination ingress into the bearing housing, which is the primary cause of shortened bearing life.

Solution: The BPD – Designed for the conditions encountered by centrifugal pumps

Problem 2: To combat the high operating temperatures and environmental conditions, oil mist lubrication is widely used by refineries. Oil mist lubrication’s main drawback is containing the stray mist exiting through the bearing housing shaft ends, which can create environmental, health, and safety issues.

Solution: The BPD – Designed to contain oil mist lubrication

- Redundant dynamic and static contamination ingress protection independent of speed.

- No speed limitations, i.e., can be slow rolled indefinitely without damaging the seal.

- Operates effectively up to 650F in heavy steam environments.

- Split and solid designs perform identically

- Retains lubrication regardless of method

- Will not allow automatic oilers to overfill the bearing housing

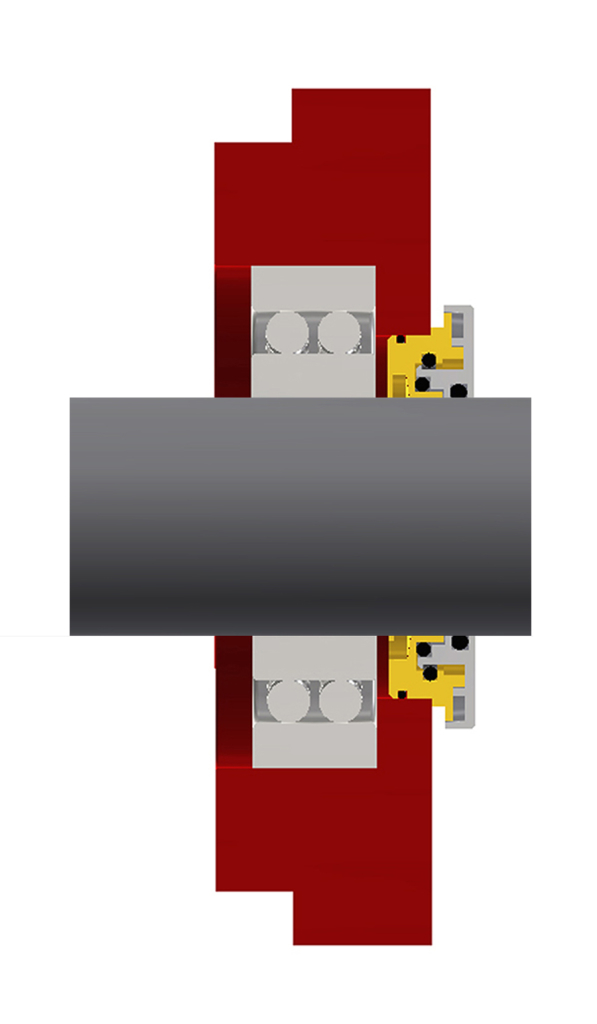

BPD

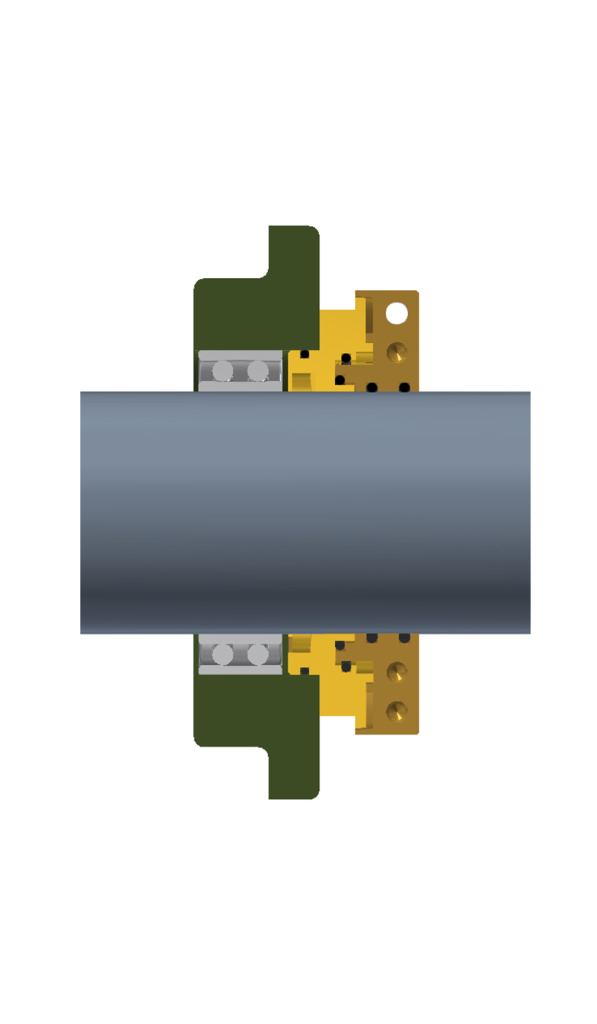

Split BPD

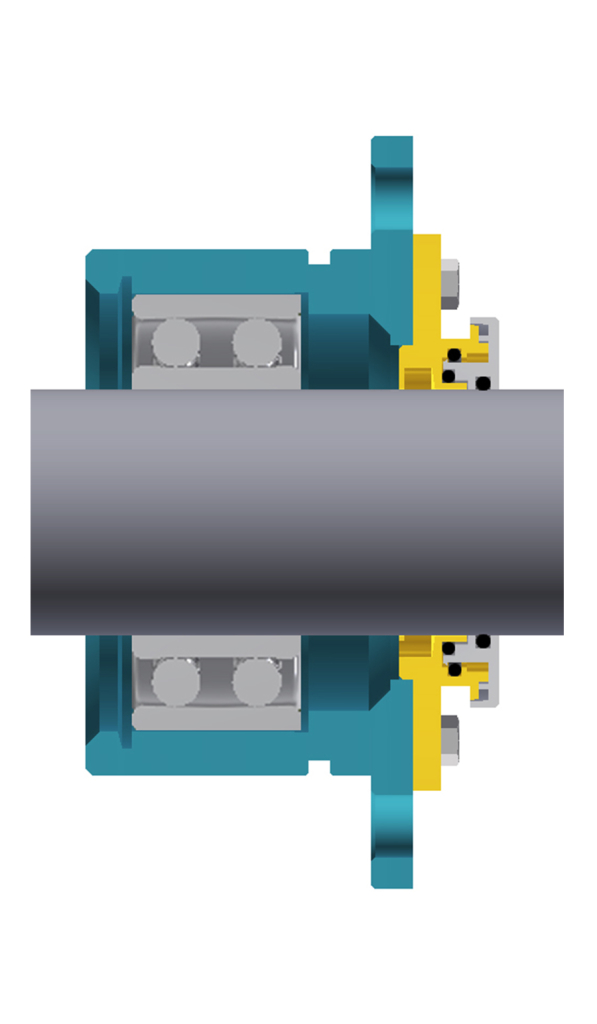

BPD-F